Aluminium & Silver Mirror

Abhishek Art Glass mirrors are produced by spraying thin aluminium or silver layer of reflective coating onto the glass which is then processed by two layer of highly resistant protective paint.

Difference in Aluminium & Silver Coating

Aluminium Coating

Standard protected aluminium is our most popular mirror coating for applications in the visible and near infrared. A coating of Silicon Monoxide (SiO) is typically used as an overcoat to protect the delicate aluminium. This treatment provides an abrasion-resistant surface while maintaining the performance of aluminium mirror.

Silver Coating

Silver offers high reflectance in the visible and infrared spectral regions, making it an excellent choice for broad applications that span multiple spectral regions. A protective coating reduces silver's tendency to tarnish but the coating still performs best in low humidity environments.

Core competency

Environmental friendly:-

• Copper and lead free.

Increased Durability:-

• Special double coating of paint increases the life of mirror.

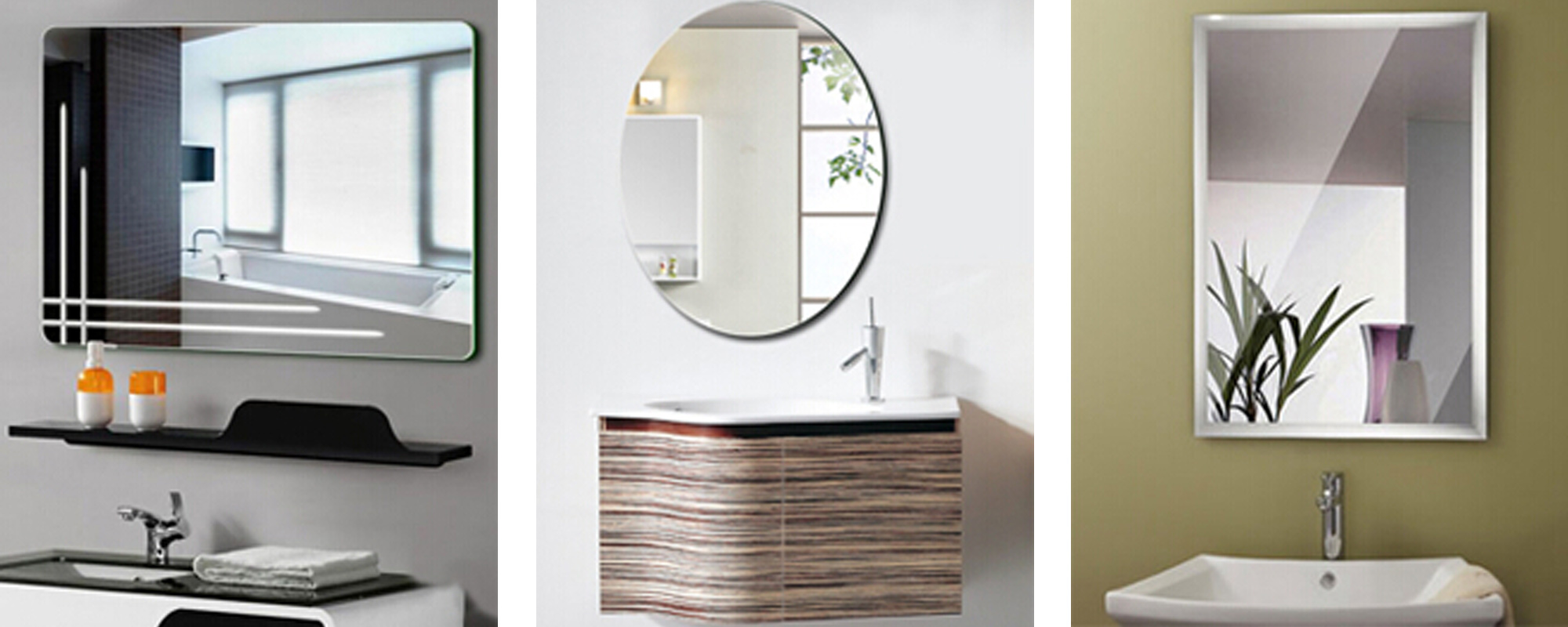

Applications:

• Direct Domestic use.

• Can be customized by sandblasting, non-acidic etching, and completely suitable for processing.

• Edge worked such as bevelled, C-edge, Drill, and Groove etc are possible.

Sizes

Thickness: 2 mm - 8 mm

Sizes : 1830 mm x 2440 mm Customised sizes also available.